Southern California Edison

Transforming business processes to support continual improvement

CLIENT PROFILE

Southern California Edison (SCE) has delivered electricity to Southern and Central California for more than 125 years. SCE requires efficient operations and clearly defined processes in order to ensure compliance and keep essential services’ costs to a minimum.

CHALLENGE

SCE sought the support of erwin to address its process management challenges. Ryan Maddox, Process Improvement Manager, explains, “Utilities are complex organizations. None of our business functions operate in isolation, so we have a series of interconnected multi-step processes that need to work every time. These processes are all supported by multiple applications and software solutions, which means a problem in one area will almost certainly have a downstream effect in another. Our job is to make sure it all runs as smoothly as possible.”

SOLUTION

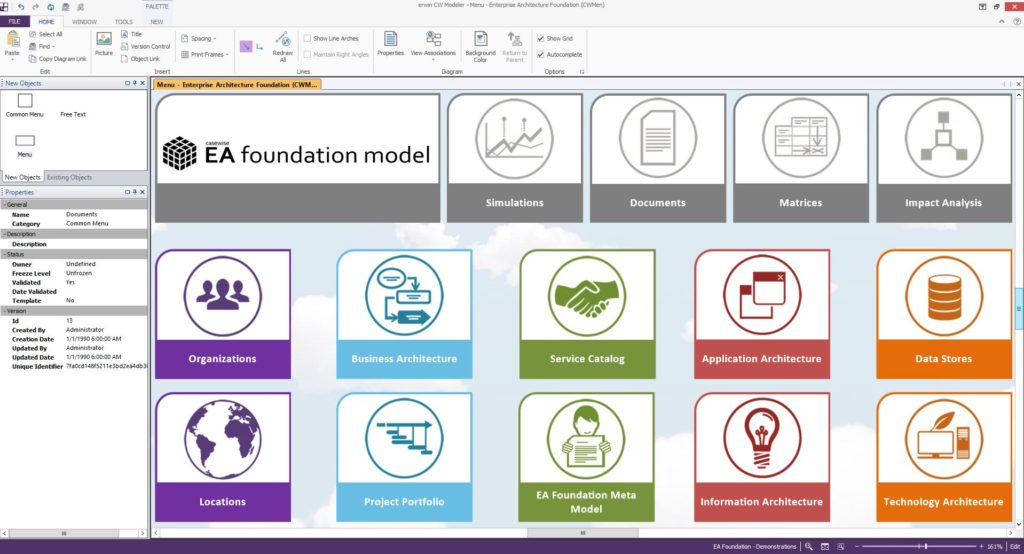

After evaluating various enterprise architecture enterprise architecture solutions, erwin stood out because it offered the right balance of cost and functionality. “There were other tools that met our requirements, but they were more costly. With erwin, we’re

in a better position to create a more comprehensive picture of our business process requirements and communicate our business needs to the IT departments. erwin’s consultants helped us develop a better understanding of what our business could be in the future,” explains Maddox.

One of SCE’s key corporate values is continuous improvement. “Our original requirements were very different to those we developed later,” says Maddox. “Our original implementation of erwin solutions was more focused on documenting, analyzing and simulating processes in a central repository and then managing that repository. As we continued to focus on different process improvements and software implementations and developed the relationship between our business users and the IT department, our use of erwin progressed.”

“The most important factor was the level of flexibility that erwin offered. We needed an adaptable solution and erwin delivered. It was exactly the user-friendly and highly customizable solution we wanted. We now have a clear view of who is impacted by our change projects, and the communication and access they need,” says Maddox.

“erwin gives us a high-level blueprint of the processes and key information required to manage change using simulations and scenarios. We’ve used erwin to identify employee training requirements and to pinpoint potential trouble spots and bottlenecks in proposed changes.”

RESULTS

During a major SAP integration, Maddox says erwin helped reduce the stabilization period from three to six months to three weeks for what he calls “the smoothest implementation ever.” They realized additional savings by reducing the time spent writing lengthy technical procedures. “We estimate that it’s probably saved us technical writing resources, paying for itself within a year, and we fully expect further savings in the future.”

SCE is also looking into ways to use erwin Business Process and erwin Enterprise Architecture to support company-wide initiatives for operational excellence and continual improvement. “This is one of my favorite projects,” says Maddox. “We’re developing a portal where employees can submit ideas for improving operations. With change programs people are often tempted to simply go along with projects that are the ‘flavor of the month.’ The portal will help us continue to get a fresh perspective. These are just some of the results we’ve seen from working with erwin.”

“We could have generated the right procedures over time, but we wouldn’t have had the analysis and simulation to make fully informed decisions or trained the right people and given them access to the correct information without erwin. It is one of the most important change management resources we have,” concludes Maddox.